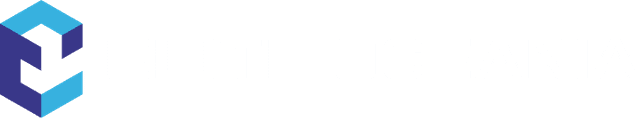

Welding Automation

Precision welds at production speed with consistent quality and reduced rework.

Automate MIG, TIG, and spot welding to address welder shortages and improve productivity. Elite Oceania welding solutions are designed for Australian fabrication environments — backed by local support.

Most suited to the following industries

Why Automate Welding?

Skilled welders are increasingly scarce. Automation delivers consistent weld quality while freeing experienced welders for complex work.

Welding Solutions Built for Australian Fabrication

Our cobots work alongside welders, handling repetitive joints while skilled tradespeople focus on complex fabrication.

Key Features

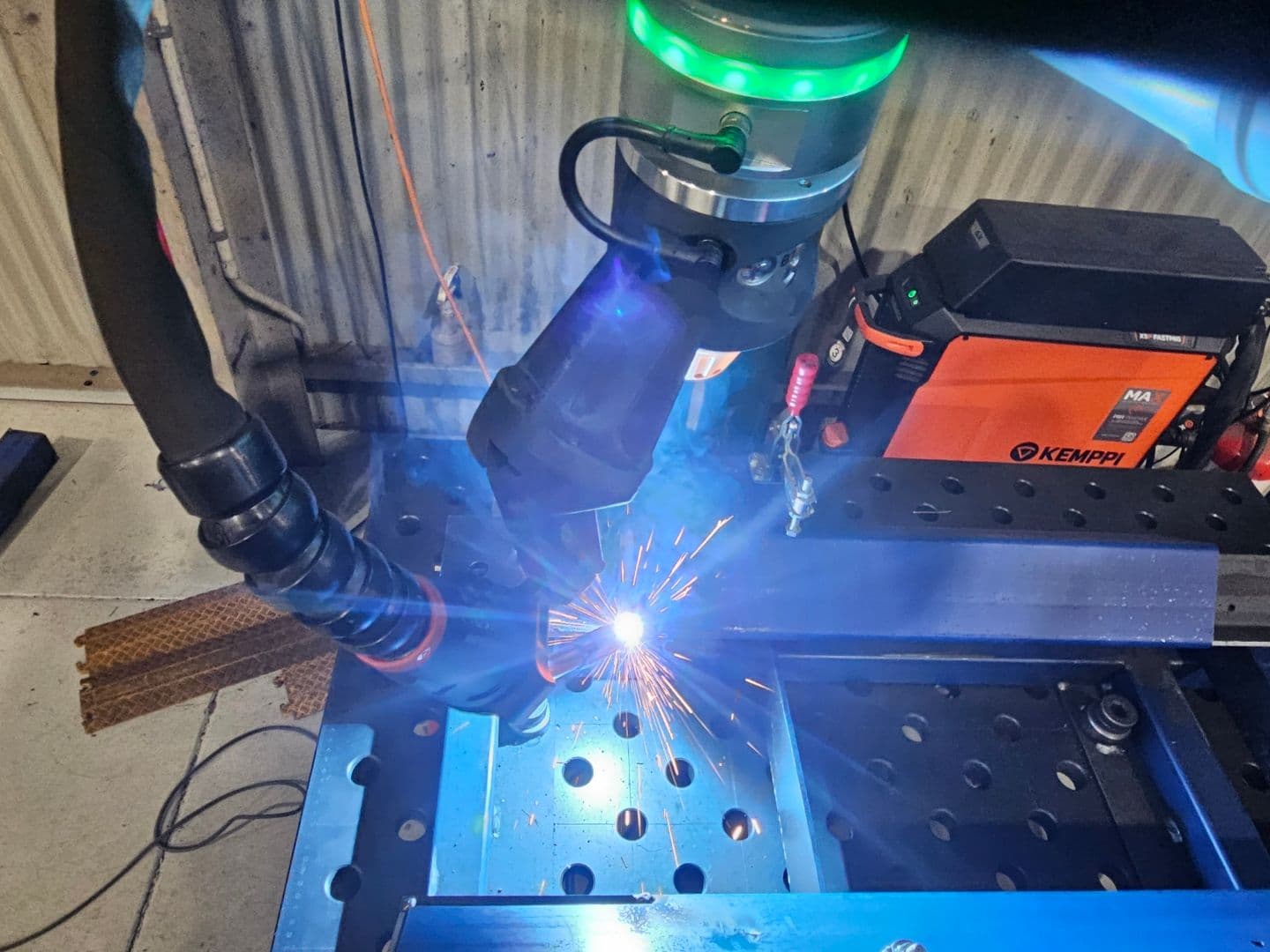

How It Works

From fixture to finished weld in three efficient steps

Locate

Touch sensing finds the workpiece position. The cobot adjusts the weld path to match actual part location.

Weld

Programmed weld sequences execute with consistent speed, angle, and stick-out. Multi-pass welds build up material precisely.

Inspect

Visual inspection confirms weld quality. Parts move to the next station or to finishing operations.