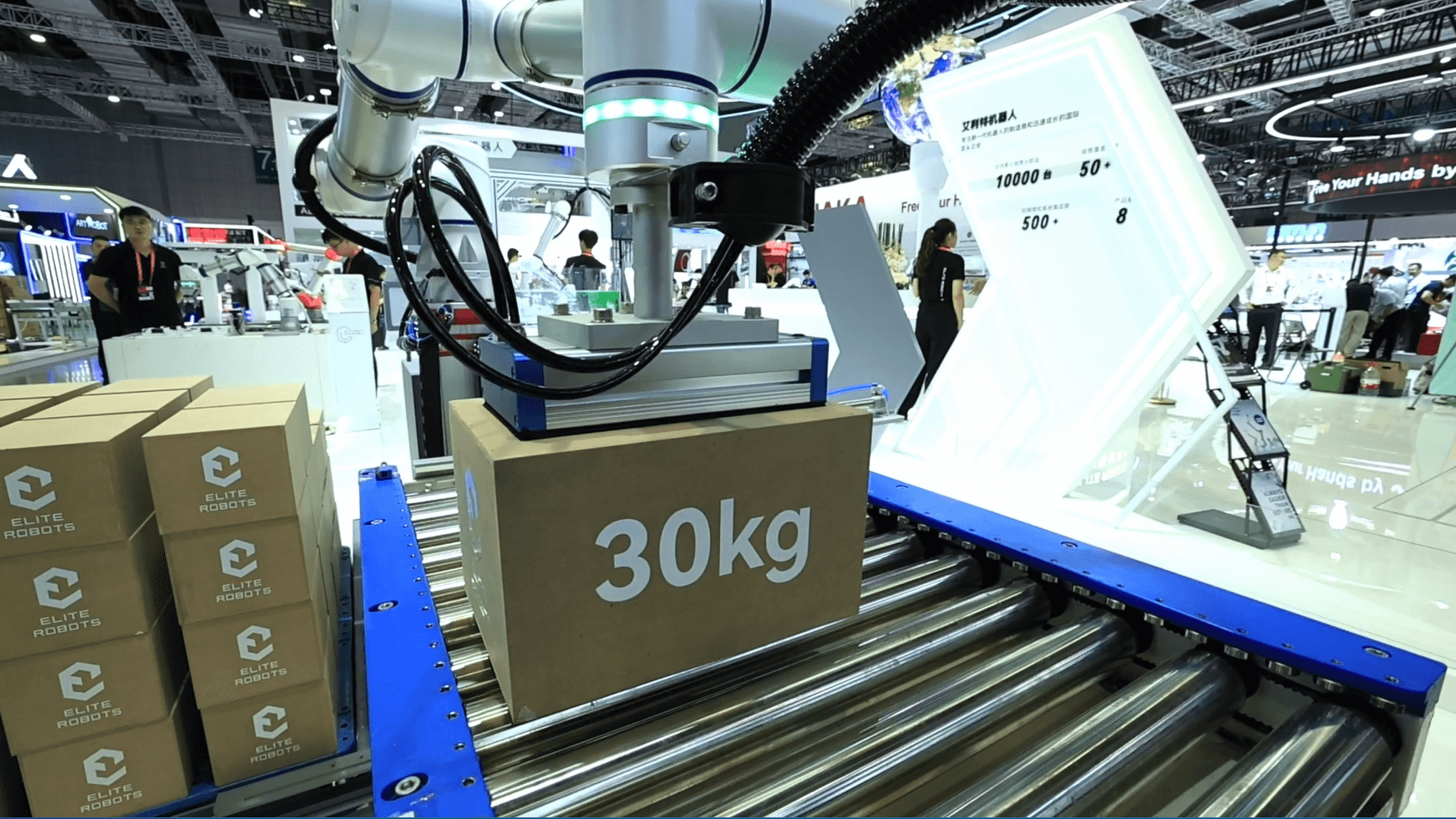

Pick & Place Automation

High-speed, accurate picking for packaging, kitting, and assembly operations.

Automate repetitive picking tasks to increase throughput and reduce strain injuries. Elite Oceania pick and place solutions deliver precision and speed — backed by local support and parts.

Most suited to the following industries

Why Automate Pick & Place?

Repetitive picking causes fatigue and inconsistency. Automation delivers reliable speed and accuracy, cycle after cycle.

Pick & Place Solutions Built for Australian Production

Flexible gripper options and vision integration make our cobots adaptable to a wide range of products and packaging formats.

Key Features

How It Works

From product to package in three efficient steps

Detect

Vision systems identify product position and orientation. The cobot calculates the optimal pick point for each item.

Pick

Precision grippers securely grasp the product. Force sensing ensures consistent handling without damage.

Place

Products are placed accurately into packaging, trays, or onto conveyors. Speed and placement are optimised for your throughput targets.

Ready to Speed Up Your Picking?

Tell us about your products and packaging requirements.